SEMICONDUCTOR FAB CUSTOM APPLICATIONS SAMPLER

(Just click on any thumbnail photo below for a bigger picture)

- Except where noted, most fab code was written in standard Tcl/tk, including the low level rs232 secs/gem interfacing (to simplify code dependencies and to keep the project costs down).

- In addition to general recipe downloading or selection and data gathering (to be put into a server database, or as a series of Excel csv files tagged with each lot and wafer for process problem debugging and six sigma purposes), the following special problems were identified for these tools and mitigated with no additional hardware expenditures:

| Tool | Problem | Sample Screenshots | |||

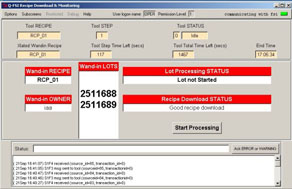

| Amat 8330 Etcher |

Multiple lots, all having the same recipe, being batched together in the tool's import port led to frequent mistakes when new lots with different recipes came along. Setup a strict queuing regimen for what was allowed to be seen on the tool's input port. Alarmed if mixed recipes would be processed together, and otherwise automatically changed recipes on the tool for new material. |

| |||

| Amat MXP Etcher |

Had fussy product mix requirements due to chamber seasoning needs. Interface with "Triant" software package in passthrough mode for corporate tool commonality. |

|

|

| |

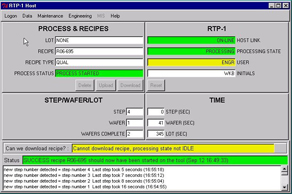

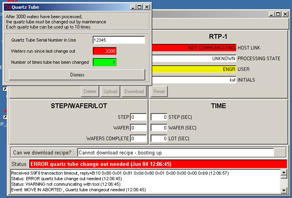

| RTP rapid thermal anneal | A finicky rs232 interface would often hangup the tool at lot finish. Halted polling at end of last wafer until wafer movement completed. Monitored conditioning wafers, tube and liner lifetimes, and prevented wandins if limits were exceeded |

|

|

| |

| FSI Cleaner |

Walking up to a tool, you didn't know whether it was done processing or not. Converted from binary to ascii recipe definitions for easier engineering recipe auditing. |

|

|

| |

| Novellus Films |

It was hard to figure out which wafers got processed if a power failure occured. Made little "wafer" circles, which turned light green upon chamber entry and dark green upon exit. |

|

| ||

| SEMY Furnaces |

Simple recipe selection on a given furnace tube of a cluster tool.

|

| |||