Ipod created in Adobe Photoshop

Ipod created in Adobe Photoshop

|

About Ken Freed

|

During high school I became interested in photography (which has long since branched off into today's interest in computer graphics), and I particularly liked darkroom work. My interest in chemistry led to a one year clinical training course after high school, and I received my ASCP-CLA (hospital lab tech) certification in 1973.

Owing to the recession at that time, hospital lab tech jobs were hard to find. I became an apprentice in a machine shop for the next 2 ½ years helping to make blow molds, and some injection and compression molds. Most of my time was spent roughing out blow molds in front of a Bridgeport milling machine, with some surface grinding and lathe work.

The machine shop experience fostered an interest in engineering, and in 1976 I started college, planning on becoming a mechanical engineer. College awakened my previous interests in chemistry, electronics and computers however - and I wound up getting degrees in chemistry (with a third of the Masters degree coursework completed, concentrating on organic chemistry with research on stereo selectivity in sulfones), chemical engineering and a (near) minor in electrical engineering (concentrating on analog and digital circuits).

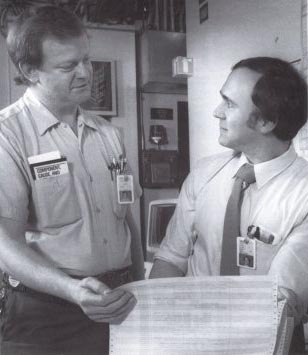

During my last 3 years in college, I switched from picking up Saturday machine shop work, to working the weekend shift and holidays as a lab tech at Riverside Hospital (now St. Clare's) where I had trained to be a lab tech a few years earlier. I also took a semester and summer off from college between chemistry and chemical engineering degrees to work for GAF Corp, as a chemical engineering co-op (collecting binary vapor liquid equilibrium data to model the use of GAF's n-methylpyrrolidone as an extractive distillation agent for the separation of ethyl benzene from the styrene monomer in polystyrene production).

After college I joined IBM Endicott

(in what would eventually become part of the

Microelectronics

division) as a way of using both chemical and electronic backgrounds. After a year as a chemical engineer in Additive Copper Plating, in 1982 I transferred to IS (information services) and went on to become an expert at writing tool interfacing applications to address production and engineering needs. Although my initial focus was on getting the data out of machines and correlating it to (good and bad) product so engineering could figure out what was wrong, the time spent in the lab and machine shop provided insight into the types of things that easily go wrong in manufacturing. As a result, the software I developed was sought after by manufacturing production operators and managers alike. From there, I branched out into real time multitasking embedded tool control (using IBM Series/1 computers, which are similar to today's C language PLCs), CAD data preparation for 2D circuit board image photolithography, and MES (manufacturing execution system) software.

After college I joined IBM Endicott

(in what would eventually become part of the

Microelectronics

division) as a way of using both chemical and electronic backgrounds. After a year as a chemical engineer in Additive Copper Plating, in 1982 I transferred to IS (information services) and went on to become an expert at writing tool interfacing applications to address production and engineering needs. Although my initial focus was on getting the data out of machines and correlating it to (good and bad) product so engineering could figure out what was wrong, the time spent in the lab and machine shop provided insight into the types of things that easily go wrong in manufacturing. As a result, the software I developed was sought after by manufacturing production operators and managers alike. From there, I branched out into real time multitasking embedded tool control (using IBM Series/1 computers, which are similar to today's C language PLCs), CAD data preparation for 2D circuit board image photolithography, and MES (manufacturing execution system) software.

After 14 years with IBM manufacturing (during which time I completed a Master's Degree in Computer Science with an emphasis in project management) and 3 years with Applied Materials (as the sole Ion Implant embedded software support engineer in the US), I spent 2001 through 2008 as the site Automation Engineer for Cypress Semiconductor in Round Rock, Texas.

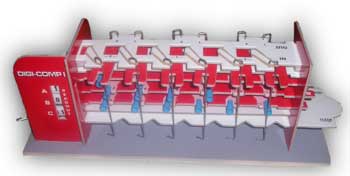

I've always had an interest in electronics and computers, and I programmed my first mechanical

I've always had an interest in electronics and computers, and I programmed my first mechanical

I programmed my first

electronic computer,

I programmed my first

electronic computer,